When I first arrived at the Folk School I was excited about trying my hand at the forge, but then I promptly came down with a sinus infection and it seemed like a bad idea to be in the middle of a soot and smoke cloud for a week. All of a sudden months had gone by, and I realized that if I wanted to try, I'd better get in a class quick. Luckily for me there were several spots open in Susan Hutchinson's class, and she is awesome! It turns out I really, really liked being sooty all week. (I also learned that I really like operating a drill press). On the pro side of blacksmithing: I made so many things that I've wanted for a long time, and also my grey work pants and I have bonded. On the con side: I see so much coal when I blow my nose that I wonder if I'll end up with black lung. Also, I burned my hand a few times, but that's no big deal.

Here's my end-of-the-week haul!

We all made a sweet pair of barbecue skewers as our 1st night intro project:

Then I moved on to racks of hooks. This was my main goal in taking the class. My FMIL (future mother-in-law) Patty has an awesome iron rack of hooks on which all her necklaces are hung. I'll fess up to having coveted it for years. Rather than continue to stroke it every Thanksgiving break, I made my own, with twelve hooks on it. (In the photo at the top of this entry, it's the curvy rack with, well, the twelve hooks). Then I made a mini version for our keys, to be hung near the front door. Here's the key rack, ready for assembly:

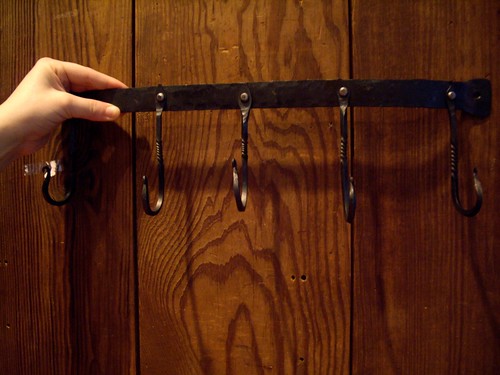

And here it is, all neatly put together and oiled.

(excuse the iPhone pic).

A detail that I really like from the jewelry rack:

Here's the next rack I made, with bigger hooks, intended for our coffee cups and to be hung near the kettle.

I really love that it curves out from the wall. I can't wait to see what our mugs look like on it!

I ended up making another rack late last night, because I had so many extra hooks left over. (I also really liked making hooks. Who doesn't?) The whole week I had been hammering my steel by hand, as well as building a coal-burning fire in my forge by hand. Susan and a few of the more experienced students in class had fired up a propane forge and were also using a gigantic, scary-looking hammering machine (I'm sorry I don't know what it actually is called), and they were getting their work done super fast. So I tried making this last rack in the propane forge and hammering it with the hydraulic machine. Here's the difference:

(hand hammered is on the left, machined is on the right).

One of the less obvious benefits to using the propane forge is that no matter how long you keep your steel in the fire, it will not burn. Somehow the forge only gets hot enough to make your piece glow, but it will never spark (bad) or burn (very very bad). Huh. So yeah, there are some burn marks on all my other pieces. But I also really like the hammer marks that a human makes. They're both good methods, and I'm glad I learned both.

The very last project I completed was a pair of brackets for a shelf. This was tough because a) it was the biggest steel I had used and b) I needed them to match almost perfectly. Here they are, in progress and then at the exhibit:

So, any blacksmith who is reading this has probably already said to themselves, "oh, she totally cheated. Those (small) hooks are horseshoe nails!" And it is true. For the small hooks that I used on three of the racks, I used horseshoe nails instead of cutting round or square stock (long bars of metal). This, I have heard, is blacksmith cheating. However, my racks are so pleasing that I do not mind at all having "cheated." I mean, I still had to heat them correctly and pound out the heads and curl the tails and shape the hooks! And drill the holes (squee!). It was a lot of work for a beginner.

(Horseshoe nail as god intended, and after being manipulated by a cheating cheater).

All in all I'm super glad I got to take blacksmithing, and am glad I took it from Susan. By the end of the week I was starting to see how addicting it could get. I do miss my nice soft yarns, though. And fabric. It's hard to burn yourself on yarn.

1 comment:

My husband and I spent a week at JCC a couple of years ago. He took blacksmithing and I took spinning and dyeing cotton. It was a GREAT week! You can check my blog for May 13-19, 2007 posts to see all about our adventure. You can also check out www.kerrlake.com/robinsnest for more pictures. It is truly a wonderful place. Now, my husband has an antique forge, a gas forge, and two anvils.

Post a Comment